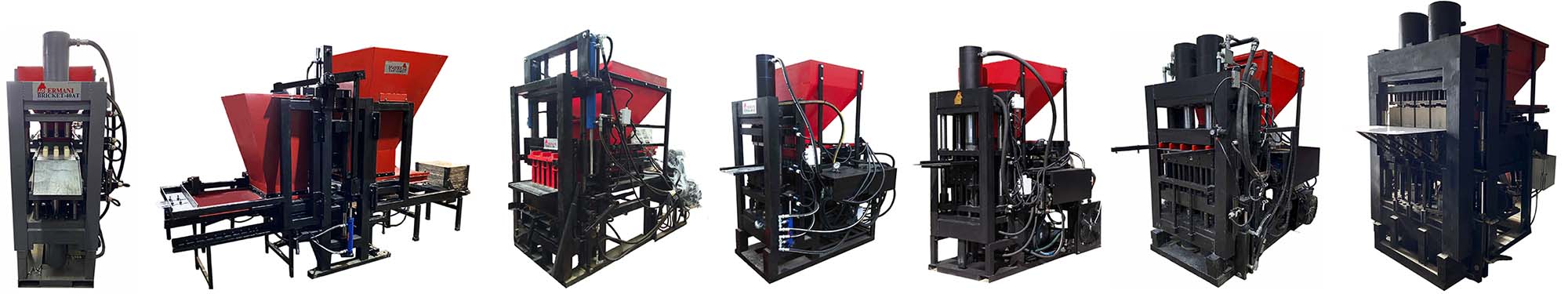

ERMANI HIPER-500AT

ERMANI hiper-500AT — hydraulic press, universal. For the production of small-piece concrete products by semi-dry pressing.

On this model of the machine it is possible to produce the following products:

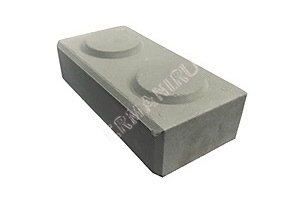

— Solid brick, hollow brick, 3D brick, figured brick.

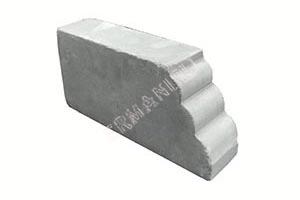

— Paving slabs: square, brick, rhombus, «double T» and other types under the order.

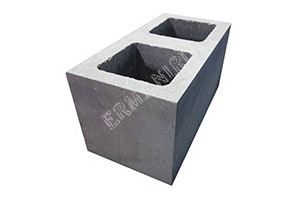

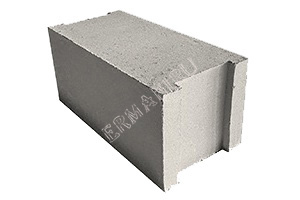

— The building block is hollow, solid, Block 3D with grooves, curbs and other large-sized concrete products.

— Facade tiles.

— Reinforcement retainer.

| Specifications | |

|---|---|

| Parameter name: | Meaning: |

| Pressing pressure, tons | 400 / 500 |

| Pressure in the hydraulic system: nominal / maximum (MPa) | 18 / 24 |

| Main cylinder diameter (mm) | 280 |

| Machine dimensions, weight: | |

| Length, width, height (mm) Weight: (kg) | 2300 - 2100 - 2800 5570 |

| Calculations: | |

| Number of products per cycle: brick / block / paving | 12 / 4 / 16 |

| Duration of one cycle, (seconds) | 20-25 |

| Productivity, pieces / hour | 2160 / 720 / 2880 |

| Electric motor power, (kW) operating / maximum | 15 / 30 |

| Working mode: | |

| Loading the mixture into the chamber: | automatic |

| Product molding: | automatic |

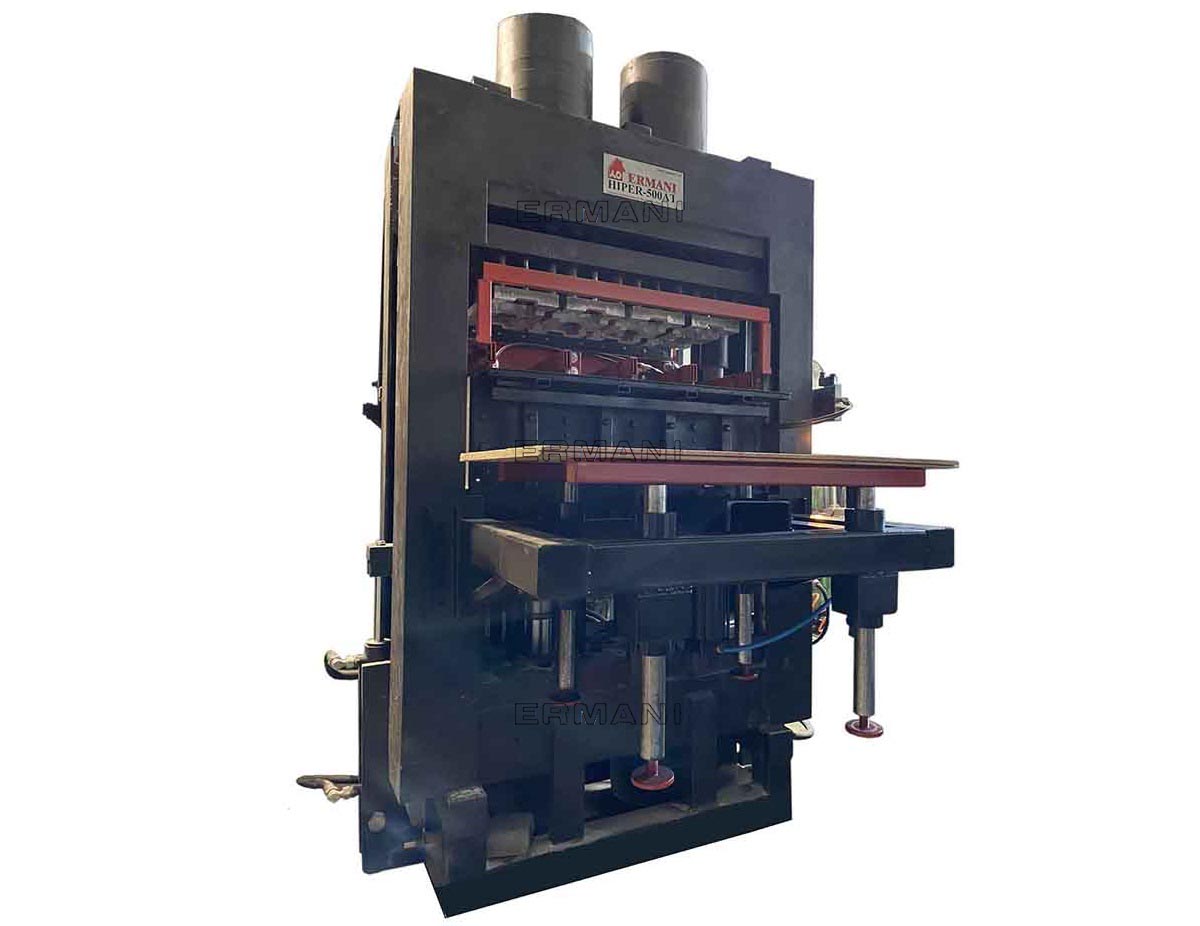

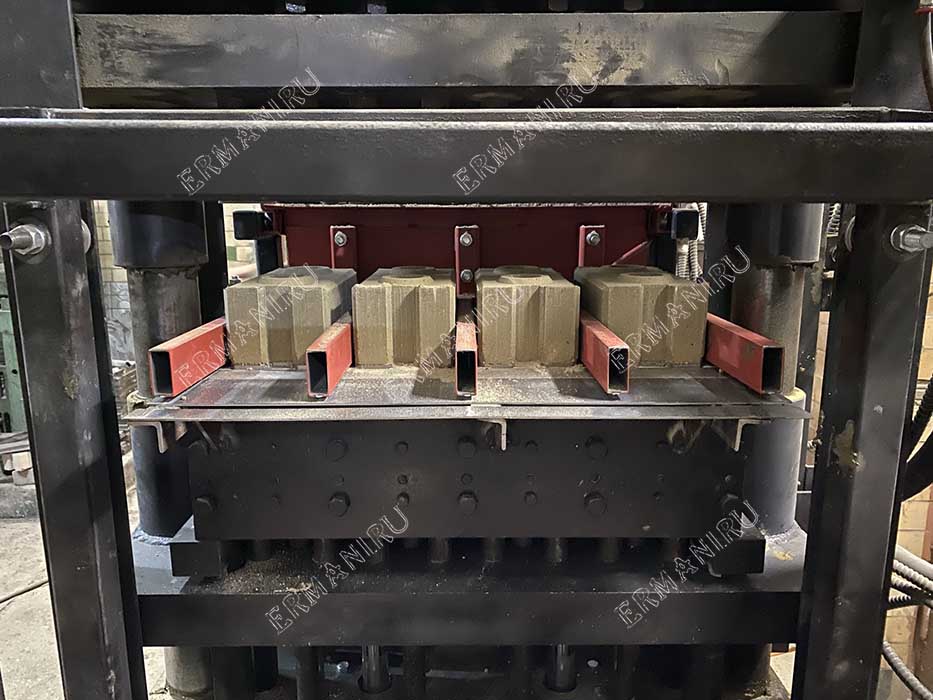

Appearance ERMANI hiper-500AT

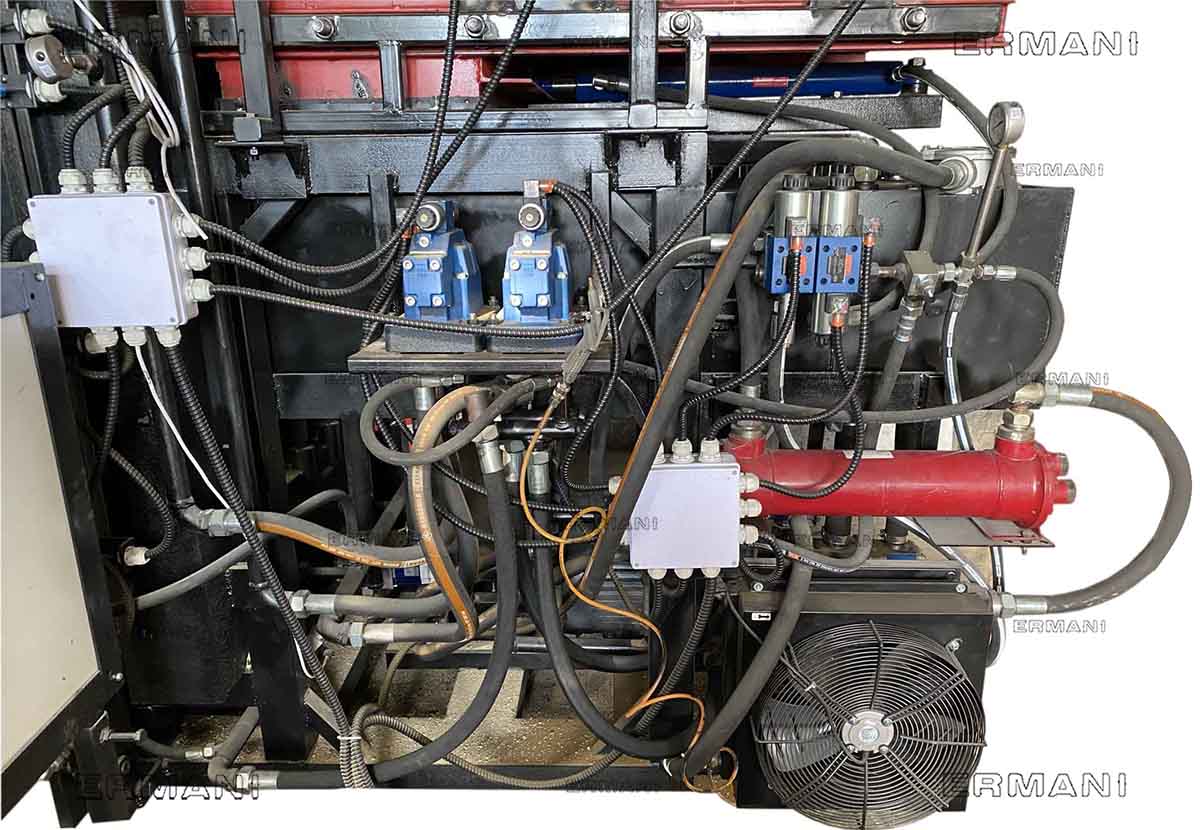

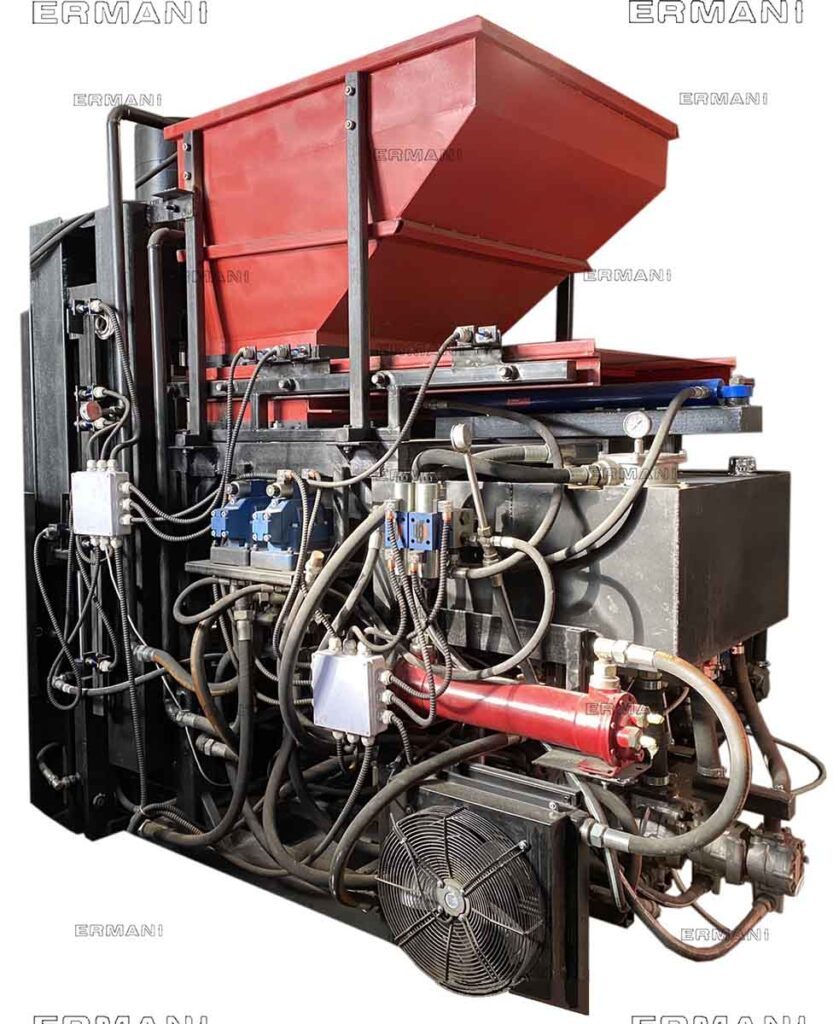

The frame of the ERMANI hiper-500AT equipment is compact and does not require additional adjustment work at the customer’s site.

The hydraulic oil station is located inside the frame, thus the machine looks very compact.

Two types of oil cooling: air or water. Guaranteed operation of the hydraulic system 24 hours a day. For hotter regions, it is recommended to enable the water cooling option.

Hydraulic components are assembled from trusted global brands. Only high-quality and reliable hydraulic distributors, valves and accessories.

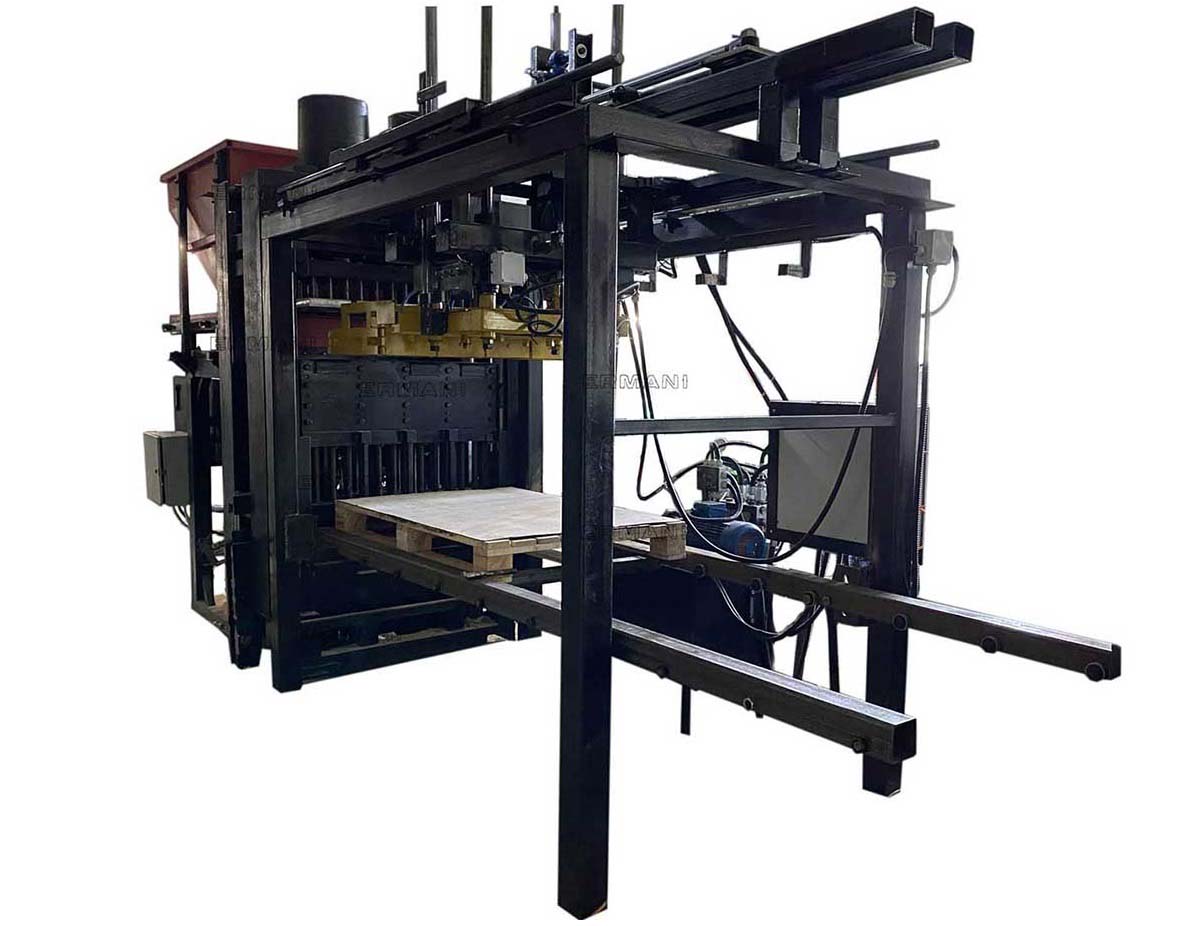

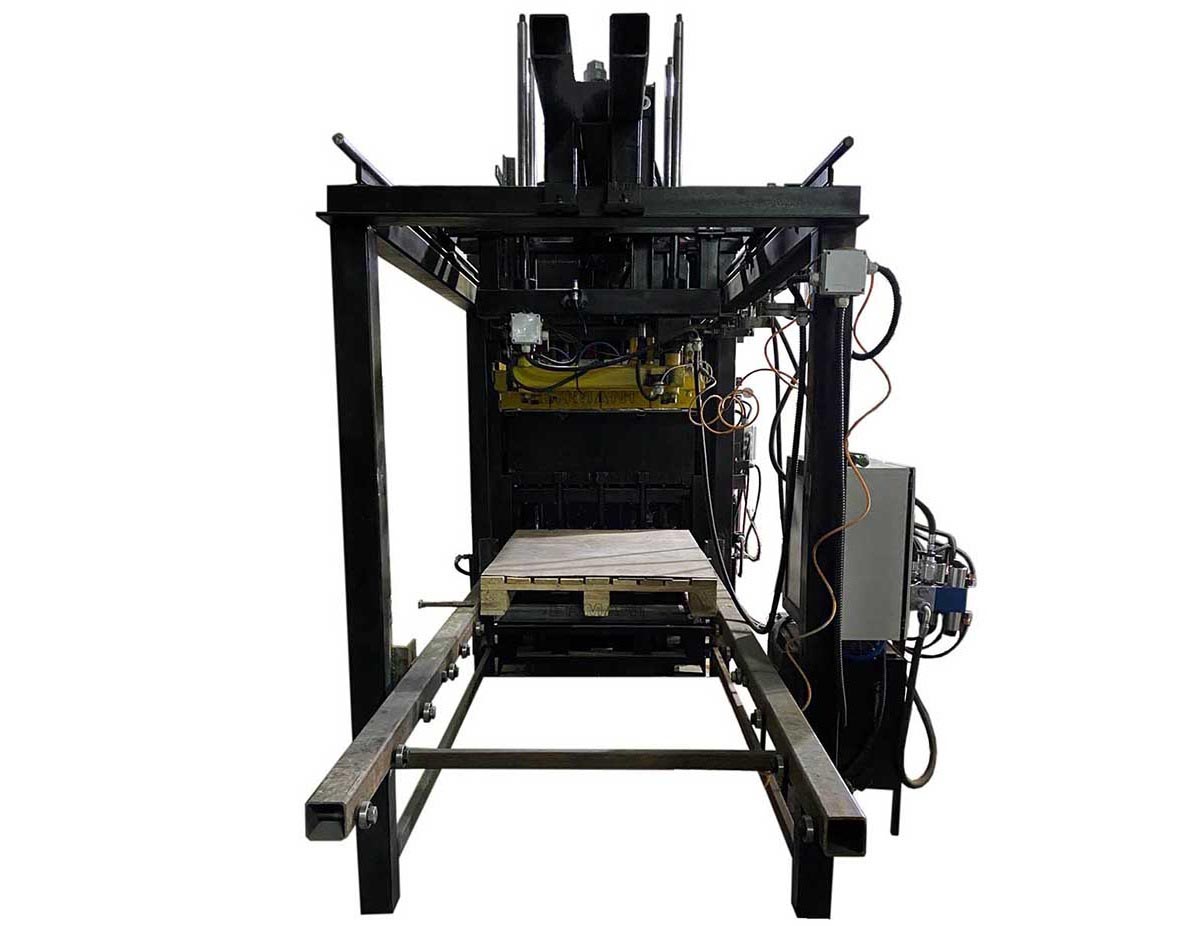

Robot stacker for ERMANI hiper-500AT

The robot stacker for the ERMANI hiper-500AT press has the ability to capture products with a large weight of up to 200 kg and more … This makes it possible to carry large blocks onto a technological pallet.

Feature of the technical part of the robot is as follows: Reinforced frame. special rollers that can withstand a lot of effort when sliding along the rails, as well as an increased diameter of rod-columns for a stable gripping stroke at the designated coordinates.

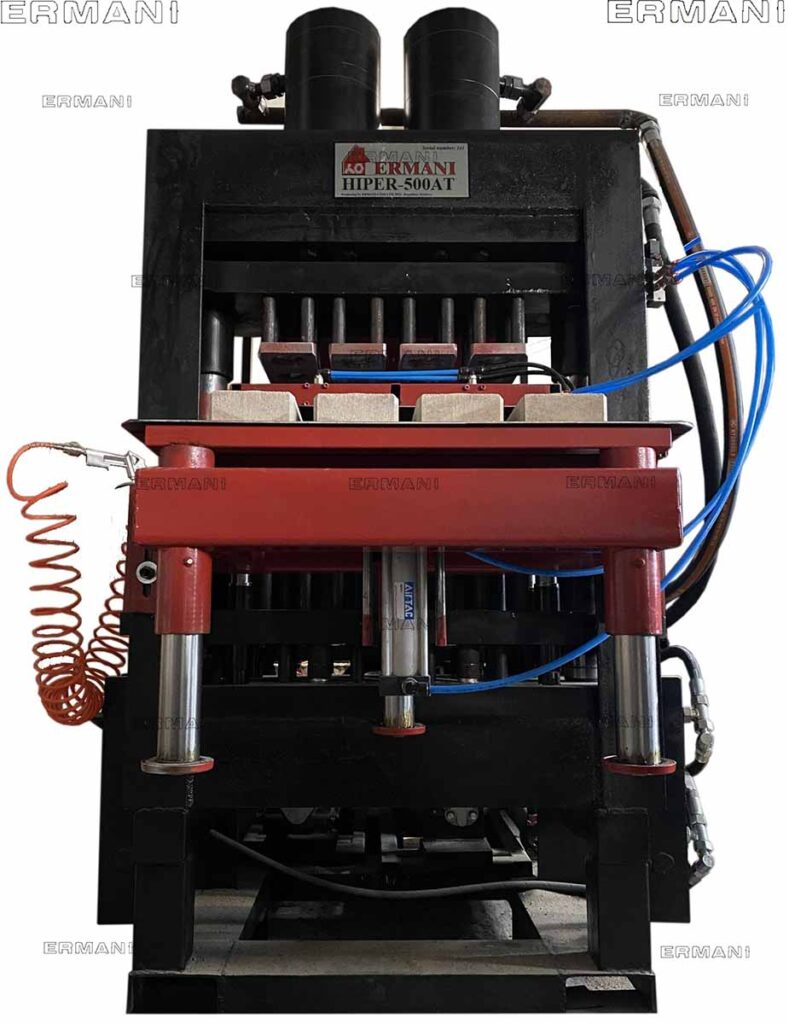

Elevator for ERMANI hiper-500AT

Elevator for press ERMANI hiper-500AT A simpler version of product removal. The process of transferring a product to a work table or processing pallet, after which it is necessary to manually remove the pallet with products or using a forklift or a pallet. Then take it to storage.

Lift for the press ERMANI hiper-500AT It is also possible to fold the finished products in several vertical rows. For example: up to 3-4 rows of large blocks and up to 5-6 bricks.

Forms (matrices) are made of special wear-resistant steel, which undergoes special processing and hardening for reliable long-term operation.

One of the few examples of products that can be produced on equipment ERMANI hiper-500AT

Press operation video ERMANI hiper-500AT