ERMANI HIPER-40AT

ERMANI hiper-40AT — hydraulic press, universal. For the production of small-piece concrete products by the method of semi-dry pressing.

On this model of the machine it is possible to make the following products:

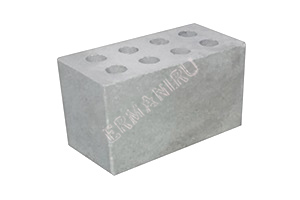

— Solid brick, hollow brick, 3D brick, figured brick.

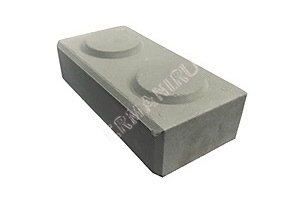

— Paving slabs: square, brick, rhombus, «double T» and other types on request.

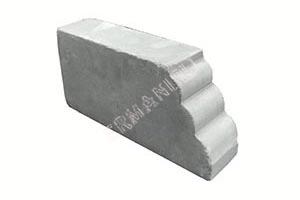

— Facade tiles.

— Reinforcement retainer.

| Specifications | |

|---|---|

| Parameter name: | Meaning: |

| Pressing pressure, tons | 40 |

| Hydraulic pressure: nominal / maximum (MPa) | 18 / 24 |

| Main cylinder diameter (mm) | 160 |

| Machine dimensions, weight: | |

| Length, width, height (mm) Weight: (kg) | 1400 - 1250 - 2100 1800 |

| Calculations: | |

| Number of products per cycle: brick / paving slabs | 1 / 2 |

| Duration of one cycle, (seconds) | 15 |

| Productivity, pieces / hour | 240 / 480 |

| Electric motor power, (kW) operating / maximum | 5 / 11 |

| Working hours: | |

| Loading the mixture into the chamber: | automatic |

| Product shaping: | automatic |

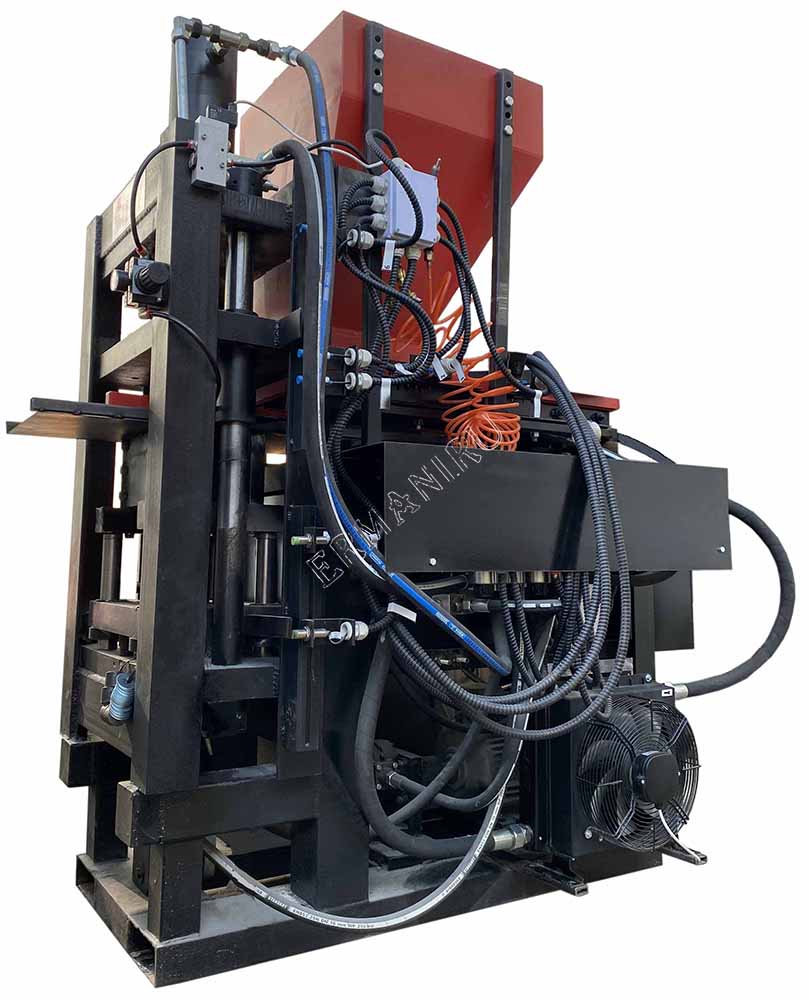

Appearance ERMANI hiper-40AT

The hydraulic components are assembled from proven global brands. Only high quality and reliable hydraulic valves, valves and accessories.

The hydraulic oil station is located inside the frame, thus the machine looks very compact.

There are two types of oil cooling: air or water. Guaranteed operation of the hydraulic system 24 hours a day. For hotter regions it is recommended to turn on the water cooling option.

The frame of the ERMANI hiper-40AT equipment is compact and does not require additional setup work at the client’s site.

The ERMANI hiper-40AT pneumatic system is assembled from Italian components. Easy and intuitive air pressure control.

The most transparent management system. Any changes and updates to the program can be made online. There is no need to call a specialist to the production facility.

Intuitive and simple control menu. Any operator can start and operate the equipment by reading the start-up instructions.

Reliable inductive proximity sensors complete the task in a matter of milliseconds.

The molds (matrices) are made of special wear-resistant steel, which undergoes special processing and hardening for reliable long-term operation.

Examples of products that can be produced on the ERMANI hiper-40AT equipment

Video of the ERMANI hiper-40AT machine