ERMANI BRICKET — for the production of technoplankton

ERMANI BRICKET is a universal hydraulic press. For the production of technoplankton and cake.

This press can produce all types of technoplankton and cake by size: D25, D28, D30, D32, D35, D36, D38, D40, D42, D50, R50 and other types of squares, round, oval, rectangular, at the request of the client …

ERMANI BRICKET — for the production of technoplankton are divided into three types:

ERMANI bricket-20AT

Automatic press — equipment for the production of technoplankton and cake. Productivity of a standard size of technoplankton F35: 720 pieces per hour.

| Specifications | bricket-20AT |

|---|---|

| Parameter name: | Meaning: |

| Pressing pressure, tons | 20 |

| Hydraulic pressure: nominal / maximum (MPa) | 16 / 20 |

| Main cylinder diameter (mm) | 120 |

| Machine dimensions, weight: | |

| Length, width, height (mm) Weight: (kg) | 1250 - 1150 - 2100 1450 |

| Calculations: | |

| Number of items per cycle: plankton D35 | 4 |

| Duration of one cycle, (seconds) | 20 |

| Productivity, pieces / hour | 720 |

| Electric motor power, (kW) operating / maximum | 3 / 7 |

| Working hours: | |

| Loading the mixture into the chamber: | automatic |

| Product shaping: | automatic |

ERMANI bricket-40AT

Automatic press — equipment for the production of technoplankton and cake. Productivity of a standard size of technoplankton F35: 1440 pieces per hour.

| Specifications | bricket-40AT |

|---|---|

| Parameter name: | Meaning: |

| Pressing pressure, tons | 40 |

| Hydraulic pressure: nominal / maximum (MPa) | 16 / 20 |

| Main cylinder diameter (mm) | 160 |

| Machine dimensions, weight: | |

| Length, width, height (mm) Weight: (kg) | 1300 - 1200 - 2100 1650 |

| Calculations: | |

| Number of items per cycle: plankton D35 | 8 |

| Duration of one cycle, (seconds) | 20 |

| Productivity, pieces / hour | 1440 |

| Electric motor power, (kW) operating / maximum | 5 / 11 |

| Working hours: | |

| Loading the mixture into the chamber: | automatic |

| Product shaping: | automatic |

ERMANI bricket-80AT

Automatic press — equipment for the production of technoplankton and cake. Productivity of a standard size of technoplankton F35: 2880 pieces per hour.

| Specifications | bricket-80AT |

|---|---|

| Parameter name: | Meaning: |

| Pressing pressure, tons | 80 |

| Hydraulic pressure: nominal / maximum (MPa) | 18 / 24 |

| Main cylinder diameter (mm) | 200 |

| Machine dimensions, weight: | |

| Length, width, height (mm) Weight: (kg) | 1400 - 1250 - 2100 1950 |

| Calculations: | |

| Number of items per cycle: plankton D35 | 16 |

| Duration of one cycle, (seconds) | 20 |

| Productivity, pieces / hour | 2880 |

| Electric motor power, (kW) operating / maximum | 7 / 15 |

| Working hours: | |

| Loading the mixture into the chamber: | automatic |

| Product shaping: | automatic |

| Specifications | bricket-20AT | bricket-40AT | bricket-80AT |

|---|---|---|---|

| Parameter name: | Meaning: | Meaning: | Meaning: |

| Pressing pressure, tons | 20 | 40 | 80 |

| Hydraulic pressure: nominal / maximum (MPa) | 16 / 20 | 16 / 20 | 18 / 24 |

| Main cylinder diameter (mm) | 120 | 160 | 200 |

| Machine dimensions, weight: | |||

| Length, width, height (mm) Weight: (kg) | 1250 - 1150 - 2100 1450 | 1300 - 1200 - 2100 1650 | 1400 - 1250 - 2100 1950 |

| Calculations: | |||

| Number of items per cycle: plankton D35 | 4 | 8 | 16 |

| Duration of one cycle, (seconds) | 20 | 20 | 20 |

| Productivity, pieces / hour | 720 | 1440 | 2880 |

| Electric motor power, (kW) operating / maximum | 3 / 7 | 5 / 11 | 7 / 15 |

| Working hours: | |||

| Loading the mixture into the chamber: | automatic | automatic | automatic |

| Product shaping: | automatic | automatic | automatic |

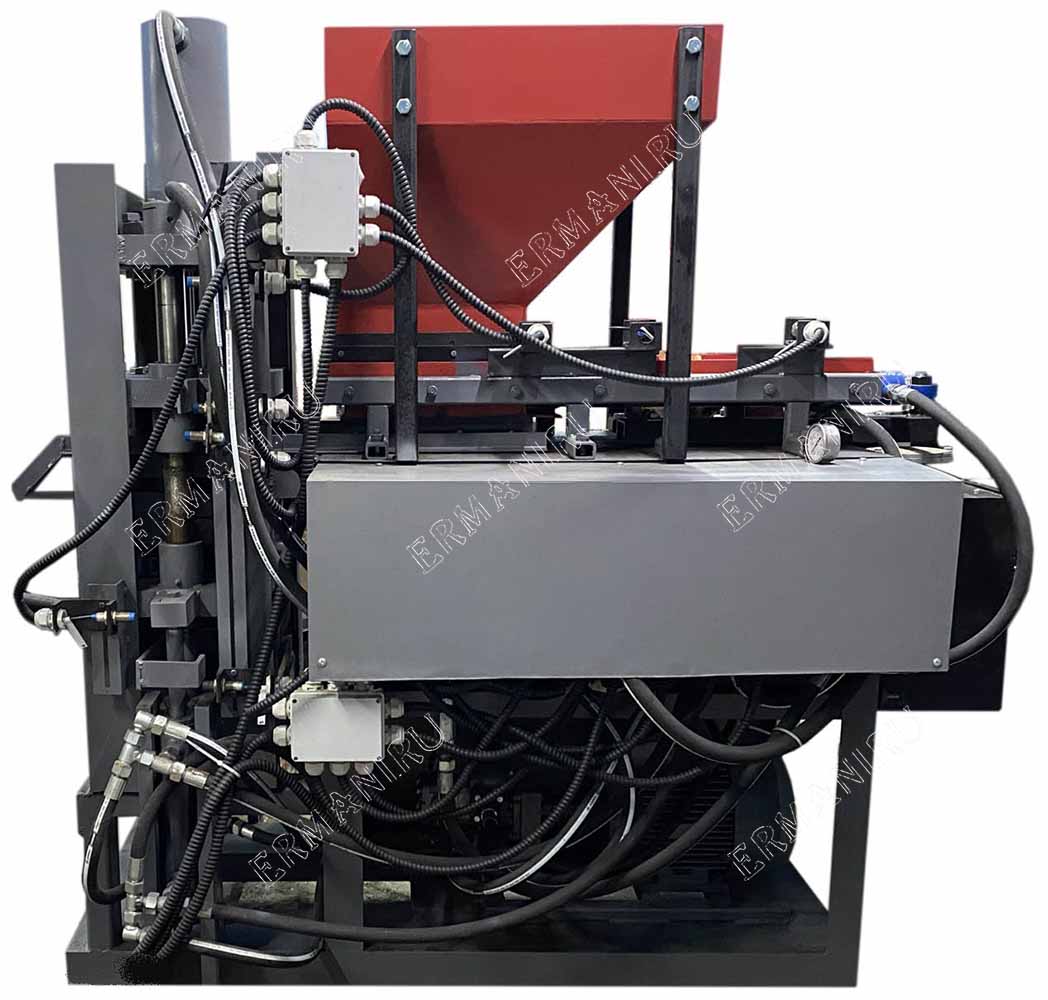

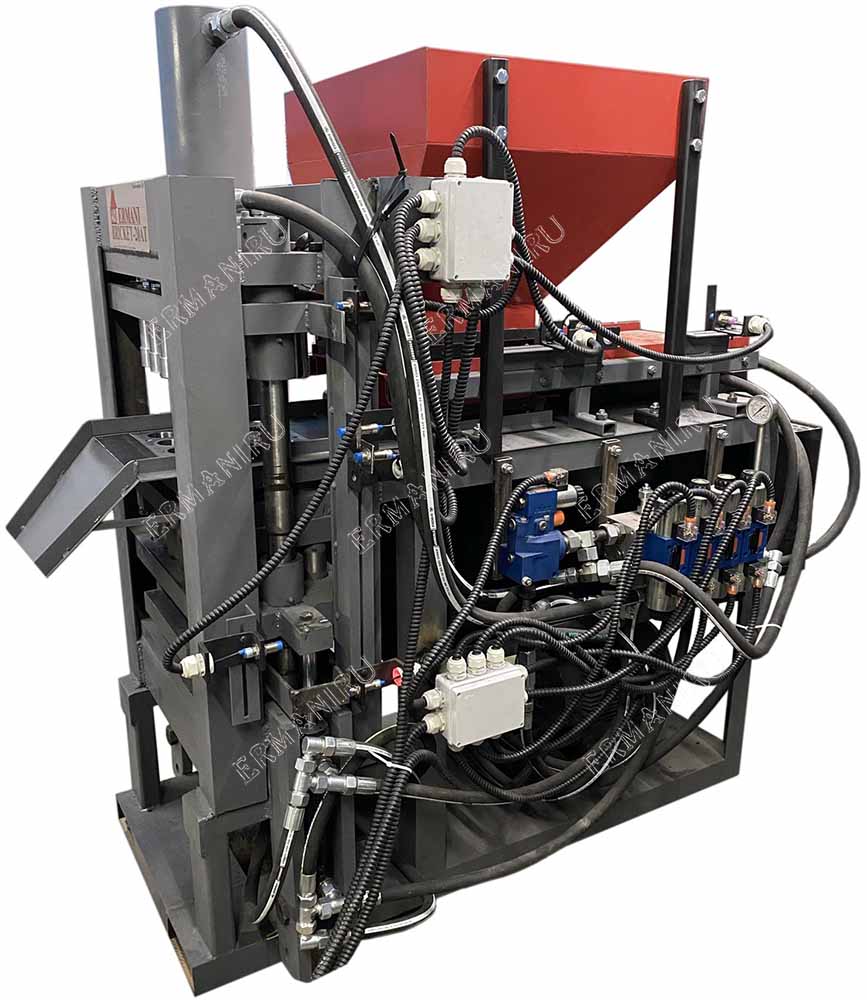

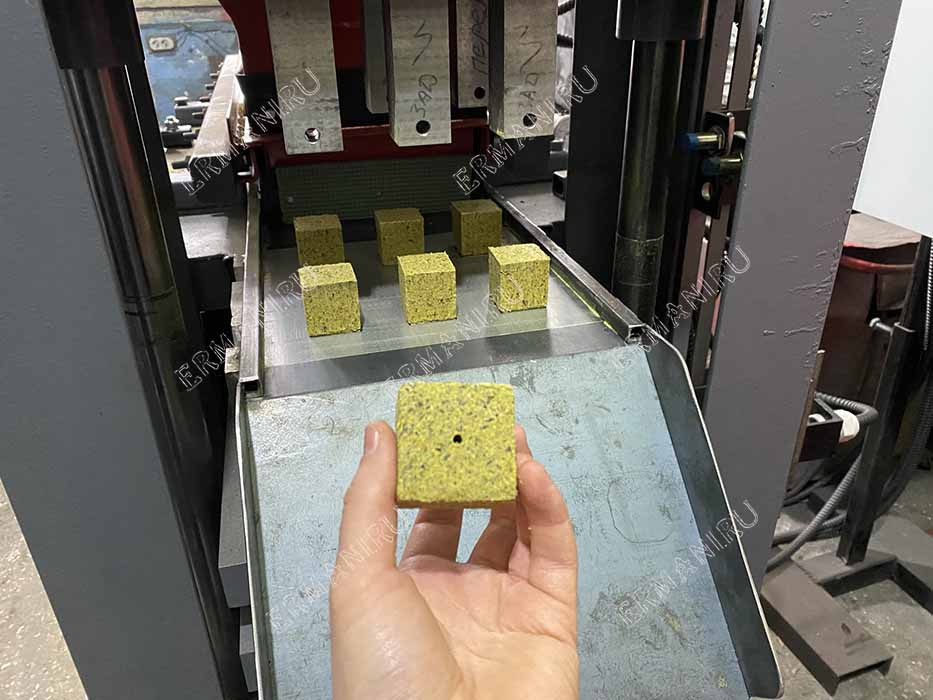

Appearance ERMANI bricket

The die — the punch is made of wear-resistant steel that can withstand hundreds of thousands of cycles when using the coarsest materials: sand, granite, crushed stone.

The frame of the ERMANI bricket equipment is compact and does not require additional adjustment work on the client’s premises.

The hydraulic components are assembled from proven global brands. Only high quality and reliable hydraulic valves, valves and accessories.

The heart of the equipment is the hydraulic cylinder, we pay special attention to the production of an important part. We use Italian rods and sleeves.

Intuitive and simple control menu. Any operator can start and operate the equipment by reading the start-up instructions.

Reliable inductive proximity sensors complete the task in a matter of milliseconds.

The molds (matrices) are made of special wear-resistant steel, which undergoes special processing and hardening for reliable long-term operation.

Examples of products that can be produced on equipment for the production of technoplankton and cake ERMANI bricket

Video of the ERMANI bricket machine